The Future In Carbon Fibre Recycling

Introduction to the technology

This recycling technology is a revolutionary and eco-friendly technology that recovers the carbon fibers from the CFRP waste material while maintaining almost all the fibers’ original properties.

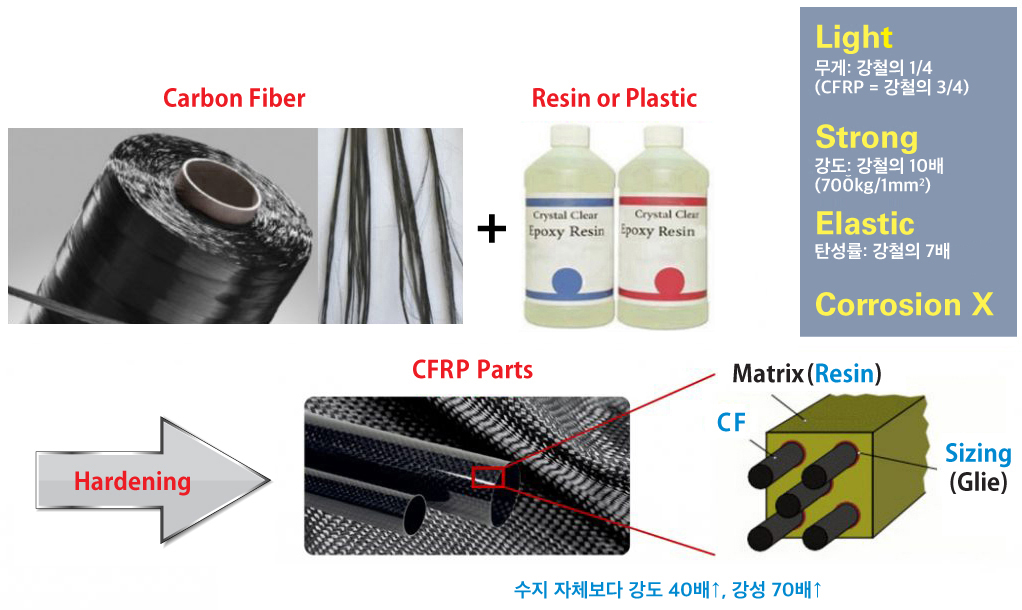

CFRP is a high-tech composite material that combines various important properties such as high strength (10 times that of steel) which is achieved by impregnation of the carbon fiber with a resin; high elasticity (7 times more than steel); and lightweight (25% of steel). Demands for CFRP are currently increasing, not only in industries such as automobile, ship, aerospace, and windmill who all strive to manufacture products at lighter weight, but also in the areas of construction/infrastructure, medical equipment, leisure and household goods where companies are always looking for superior materials.

Carbon Fiber Reinforced (CFRP)

– Carbon Fiber Reinforced Plastic (Polymer)

Use of Carbon Fiber

-For lightweight, ultra-strong, high-elasticity materials

- Early days High Profile Products ⇒ Sports/Leisure (Golf-clubs, Fishing rods), Military (Stealth Aircraft, Black Hawk, Missiles), Spaceship

- Now •Automobile, Ships, Windmills, Oil Industry (Pipes, Excavators) •Construction/Infrastructure, Sports, Medical Engineering, etc. •Environmental Industry (Air purification, Water Purifier, etc.)

Until recently, companies have been land-filling their CFRP waste because the material was difficult to recycle due to the indestructible properties of thermoset resins.

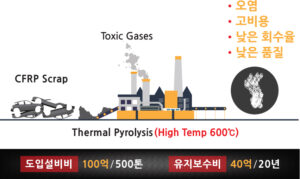

However, now that the environmental regulations are tightening in many countries, it is becoming more and more difficult to land-fill CFRP wastes. As a result, recycling, commonly done via thermal burning/incineration, has become a necessity. CFRP recycling is used for recovering the valuable carbon fibers from CFRP waste. In the method of thermal burning/incineration, the resin in the CFRP is burned off and only the carbon fibers remain. This technology is used by various companies such as ELG Carbon Fiber from the UK.

In recent years, due to increased emissions from CFRP waste and ever-stricter environmental regulations, conventional recycling methods via thermal burning/incineration require large facilities and equipment such as large incinerators to filter out toxic gases (CO, CO2, NOx, dioxin, etc.),2toxins which can cause severe air pollution. The resulting higher costs for equipment and maintenance are making the business less scalable and economical.

Another issue arises from the use of high temperatures applied to the CFRP waste during the combustion process of the thermal burning/ incineration method. Such heat adversely affects the quality of the recycled fibers due to oxidation, adsorption of impurities and other damages, and the recovery rate is comparatively low. Even though recycled carbon fibers are produced via this recycling process, the scope of application is limited due to their high cost and relatively low quality.

The Necessity for CFRP Recycling

➢ Reclamation of Resources and Diminution of Environmental Liability

- Processing Status of CFRP waste

- General Incineration to Total Incineration x (melting point = 3550 C)

- Mainly by Landfilling

- Stricter Legal Legislation

- Landfill or Incineration Process

➢ Necessity for Eco-Friendly Recycling Technology!!

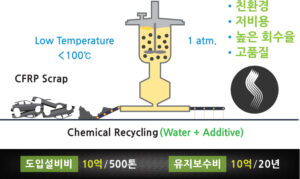

To counter the problems occurring during the conventional thermal burning method (environmental pollution, low-quality, low recovery rate, and high cost), CATACK-H uses a recycling technology that utilizes a chemical solution in combination with additives to decompose CFRP at low-temperature (<100℃) and under standard pressure (atmospheric pressure). This method, known as solvolysis, has the advantages of low cost, eco-friendliness, high recovery rate, and high quality of the recycled fibers.

CFRP RECYCLING TECHNOLOGY I

Technology used in the Past Thermal Treatment/Incineration Method(Pyrolysis)

CFRP RECYCLING TECHNOLOGY II

New Technology Chemical Decomposition (Solvolysis)

(1) Eco-Friendly Recycling Technology

The thermal burning/incineration method causes serious environmental problems. The technology used by CATACK-H, however, does not produce any air pollution thanks to the chemical depolymerization of the thermoset resin. The condensate can also be reused: the remaining solution is passed through a distillation and concentration process and the emitted substances are organic residues in a gel form. These also can be upcycled via a resin forming technology. This all makes CATACK-H ’s technology completely eco-friendly with practically zero waste.

(2) High-Quality and High-Recovery Recycling Technology

The chemical decomposition method used by CATACK-H is a technology that produces high-quality recycled carbon fibers of more than 90% of carbon fiber yarn quality (e.g. tensile strength) (95% or more in experimental data) with a recovery rate of more than 90% (95% or more of the recovered carbon fiber weight in CFRP). This is possible because there is no high temperature treatment as used in the conventional thermal burning, so there is no surface damage on the carbon fibers and the material remains intact making it possible for CATACK-H to recover the carbon fiber contained within the CFRP without any loss. The carbon fibers recovered through CATACK-H ‘s technology are very high quality, containing less than 2% decomposed epoxy residue.

(3) Economical Recycling Technology

CATACK-H ’s recycled carbon fibers via the chemical decomposition method allow for excellent price competitiveness thanks to relatively low costs of the recycling operation, high recovery rate and high quality of the fibers. The fibers can be supplied back to the market at about 70% of the price compared to recycled carbon fiber from the thermal burning/incineration method. This unique process allows CATACK-H to be competitive in the market with other recycling companies in Europe and in the United States. CATACK-H will continue to expand the supply of recycled carbon fiber to both domestic as well as international industries by offering high quality recycled carbon fibers at a competitive price.

CATACK-H produces not only their recycled carbon fibers but also intermediate products such as chopped and precision cut CF, milled CF, pellets mixed with various resins, 3D printing filaments, dry carbon fiber nonwovens (e.g. carbon paper), and applications for e.g. the automobile industry. Beyond that, we continue to invest in technology and equipment to supply new forms of applications.

Our Recycling Method

Our recycling technology is an innovative and eco-friendly technology that recovers the valuable carbon fibers from the CFRP waste while maintaining most of the fibers’ original properties and at the same time protecting the environment.

Core Competitive Strengths

CATACK-H is an innovative company that uses a revolutionary and eco-friendly technology to recycle

CFRP waste materials

that are otherwise land-filled or incinerated.

Eco-Friendly Recycling

Eco-friendly technology that uses water as a solvent

Economical Recycling

Economical Recycling thanks to an Efficient Process

High Recovery Rate

Over 90% Recovery Rate for Carbon Fiber and Epoxy Resin

Quality of Recycled Materials

High Quality of Recycled Carbon Fiber and Epoxy Resin